An Idiots Guide to Running a CNC Plasma Cutter in

Your Living Room

by Roy Mackey

The following pics show how you can run a PlasmaCam robotic cnc plasma cutter in your very own living room. Well depending on what kind of living room you have. Fortunately for me I have a live/work studio so it does make it a little easier and of course safer. Proper live/work studios are fire proof as in our case. The building is all cement, steel stud and gyproc construction. It also has a sprinkler system and numerous other fire prevention options. This is really good if you love metal work since you get to actually sleep in your shop so to speak.

Normally working at home would be a real drag since most people hate their jobs but if you love the work you do then you can’t beat it. Even if you do end up sleeping with sharp metal scraps and eating off paint covered plates!! : )

Actually, though it looks simple, it was not that easy setting my PlasmaCam up in the studio. CNC Plasma cutting machines give off piles of smoke and fine metal dust. Great if you are low on iron but if not it takes the led from your pencil, puts it in your pants and then you cannot get your butt off the chair. To contain this smoke and dust I hired the help of the heavy fire proof vynol curtains. Along with this a dual fan system. Of course the fan motors need to be sealed units so the fan does not fill up with fine metal dust and short out.

Another thing I did was cover the floor of my welding area with ten gage plate steel. This was to protect the tiles from molten metal slag created by this machine along with my regular cutting torch. This by the way has worked extremely well and looks great. I will likely be using the same when I build a new house. It is very easy to clean and any wear etc just gives it more character and on top of that fire proof and less toxic than fumy smelling (and tacky) shag rug.

Just to note I used to install carpet for a few years and ever since would not use the crap in my house. It is expensive, gives off toxic fumes, is flamable giving off very toxic smoke, and filthy too boot. The smell also takes a lot longer to fade away than most people think since our noses get used to the smell. All this not to mention it needs changed every 5 to ten years!

Anyway as you can see the plate steel looks great and works very well to protect the floor.

There are two exhaust fans in my upper window. The lower one hooks up here to act as a down draft for the table. I boxed in the sides of the machine using cement board. It is completely fire proof and cheap. I painted it black for looks.

The top fan sucks out any smoke and fumes that rise up to the ceiling. It is mounted up high for best effect. I scored this internal fan blower brand new at a local scrap yard for a mear $35. They had two but like an idiot I cheaped out on the other. They are made in Germany and very good quality! Mostly though both are sealed motors so don’t have problems with fine metal dust shorting out the motor.

This stand I made to hold the computer. My original plan was to have it inside the curtain so thus the plexiglass box to cover it. Once I changed the plan some the computer was outside the curtain and thus not really needed. It does though come in handy for holding junk on top of it when needed. Originally I had the plasma cutter, a hypertherm powermax 600 on a seperate stand but decided to combine the two. This has worked out very well. It keeps everything combined in one neat package and is easy to roll around when needed. I just bought a new 19 inch monitor to upgrade so you can see the changes I made to this stand compared to the previous pics. I find the 19" monitor hugely better when working with the plasmacam software. In order for both to fit into the plexiglass blox I had to swing the computer sideways and cut an extra opening to access the dvd drives.

By the way if you are looking for a good plasma cutter check out:

Sure you could by some cheap imported cutter that would last for years as long as you never used it. The trouble is doing that is expensive and just supports the landfill. Remember the old confucious saying.... "buy cheap.... buy twice..." It is nice knowing you have tools you can trust. It is also nice to know that if you are doing a lousy job it is not likely the tools fault!!! Narrows down trouble shooting lots.

As any good metal fabricator knows color matching is very important when setting up a welding studio. : ) This is why I had to do some searching. Eventually though I lucked out and found a very good quality blue metal bandsaw, a blue dust pan (very hard to find), blue air line, blue air blower (not shown), 50 amp extension cord, blue and yellow screw drivers, blue and yellow cresent wrenchs, blue calculator and blue and yellow needle nose plyers, blue welding goggles, blue scissors, blue file handles and a blue face shield. Hell I even found some blue regular extension cords!

The blue 50 amp extension cords was one of those real hard to find scores. One of the main reasons of course I bought the PlasmaCam in the first place was the colors matched my blue and gold macaw, Sweetie shown here checking out the tools. Sometime soon I will get the hypertherm cover powder coated in blue to match. Either that or I may bump up to the Miller 2050 I have been keeping my eye on. Of course my tig is the Miller 180 which is blue and goes well with everything also.

This was another lucky score. Finding a stand like this in the right colors was a long hunt. The yellow and blue are an almost perfect match to the PlasmaCam. Martha Stewart was very impressed!! In fact she found me the following items to add some finishing touches.

Not sure where I found these three items but either way they do add a nice finishing touch. Yellow bondo spreaders are real scarce.

This 1905 cast iron seat mounted to the newer office chair base with quick height adjust is a dream to sit on. I can sit on it staring at the wall for hours and not notice even a bit of discomfort. This works great when I am working long hours on a drawing.

My “China Lily” compressor I have jammed in an opposite corner of my welding area. It is behind a seperate curtain also but not inside the one where the cutting table is. Just to be safe though it sucks cleaner air through a copper pipe plumbed from the main part of our living area over to the compressor’s air filter. (See pic above) I will be upgrading this compressor sometime in the near future as I am not confident about it keeping up for bigger jobs. I have run it pretty steady on some bigger jobs as it just keeps up though am likely exceeding its duty cycle. Hail China but I would rather have something better quality and American made. As of now I have been fairly lucky moisture wise with one small filter on the compressor, another larger one at the plasma cutter followed by a small dessicant one and then of course the small one inside the plasma cutter itself. Considering it rains here in Vancouver once or twice in the winter I have had no moister problems that I knew of.

Here is the back side of the plasma cutter showing the two filters I have mounted. One is a dessicant and seems to work very well so far.

The PlasmaCam itself I just love. For the first while it was love hate…. ok quite awhile. At least until I threw out the operators manual. Personally I found the manual be just short of useless. My guess is the the guy who wrote it new the machine too well and made too many assumptions. Mind you my dad always said I spent too much time in the shed as a kid sharpening the wrong tool… Other people have commented that the manual is more than good enough? To me though it is one minor area where they could use some improvement

This aside, I would have to say the PlasmaCam machine is totally amazing!! The more I use it the better I like it. The biggest problem I have is with the opperator… me, not paying attention!! : )

I really find this machine a thing of beauty to watch running! Having it opens up all sorts of possiblities with metal fabrication never before possible. From the time I opened the crate it came in I could tell it was genuine good ole American quality. The company, Plasmacam Inc. seems to be very professional and one you can trust. I had it shipped to me up here in Canada and it came sooner than expected along with being packed like they intended it to arrive in one piece no fooling! I would definately buy from them again. In fact have my eye on that new Samson, www.samsoncnc.com or whatever it is called. Just started banking up the cash and justification! I figure there is still a little space over by our fridge to set it up. : ) If you want more info check out www.plasmacam.com they will send you a dvd that shows this baby in action! I would definately have to say it is as fun as it looks on the video!

For the clear vinyl I went to a local sewing supply place and scored this at about two bucks cheaper a yard than at a local industrial fabrics supply store for the same stuff. It is very heavy and virtually fire proof. I did some testing on it with my torch and no way could get it to burn or at least stay burning. I believe if I had a fire in the studio and the vinyl heated up enough and then was exposed to open flame it would likely burn on its own. Though with the sprinkler system in here and not having much flamable stuff around it is highly unlikely.

This whole curtain system likely cost me only around $500. give or take. My rough estimates for the actual vinyl welding curtain would have been around $3,000. give or take. For the track I used some good quality slider track but was not the best. I need to find some track with wheels as the fine metal dust makes the sliders stick a bit.

It must be remembered that the machine cannot be curtained off completely as the air needs to be able to get behind the curtain to replace what is getting sucked out. The same applies for the studio itself so in order to get a free flow of air into the studio I open our sliding door on the clean side. Presently I have one section of the vinyl cut out that seems to let the right amount of air flow into the area. As a cheap test to make sure the fine metal dust is not getting outside the curtain area I have rare earth magnets scattered about the studio. Though these would be useless for toxic smoke they do show me if the fine metal dust is getting into our living area. So far none except in the cutting area itself where all the magnets in there look like little balls of fur.

First I did one long curtain to separate my whole welding area from the living part of my studio. After that I did another curtain inside that area to separate the Plasmacam from the rest of the welding area. Personally I think you need this type of separation even if you have it in a normal workshop since the fine metal dust does get everywhere… NO EXAGGERATIONS!!

Of course having my parrot living with us I had to make extra sure she was not able to see the plasma cutter when operating or I would have a blind parrot before long. Now that I have had her for 24 years have gotten kind of fond of her! : )

For this I installed a track and light proof black curtain that I draw whenever using the machine or doing any kind of welding. It serves a couple of purposes actually. In the winter with the fans running the studio cools down lots except where she is behind the curtain. Soon I am going to install some of the welding vinyl onto the carriage of the machine itself. That will contain at least most of the bright light right at its source and help save my eyes! : )

Here is a shot of my loft from about where my plasmacam is now. This was before I got it so did not have the back curtain hooked up yet. The loft is where we sleep and our bathroom is.

This pic is looking towards my office area opposite our kitchen. In the cage is Sweetie. The perfectly round table top was cut on the plasmacam!

These are some window guards I made for Vancouvers famous La Cucina del Diavolo, (the devil’s kitchen) They were cut on my Plasmacam machine out of ten gage plate steel. These were one of the first jobs I did with this machine.

These I cut on the machine also. The small hole I did drill separately. I have cut holes down to .25 though I think this was a little smaller. With more practice I may get it down more I am not sure. These have also been cleaned up a little. When you have everything set right there is almost no clean up required other than a wire wheel. It is amazing!

As you can see cutting out a lot of parts is not a problem. These all look almost exactly the same also.

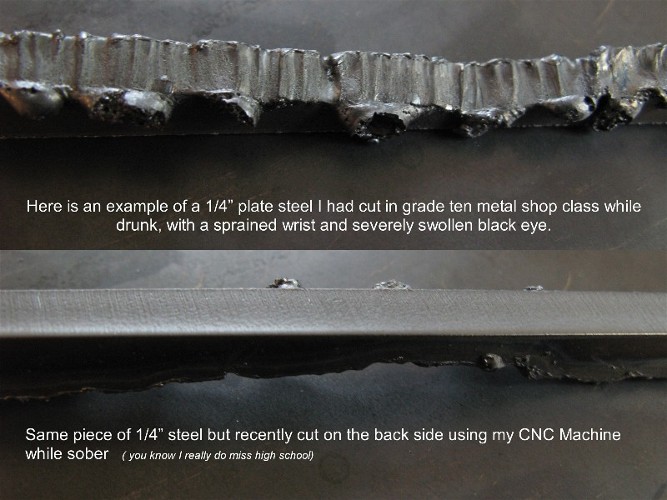

Well I think this says it all as far as cut quality verses the old method!!

Here is another piece I cut out of ten gage plate. I love flames thus www.flamingsteel.com

Just a quick note here. If you have bought or are planning to buy a plasmacam keep this number below. This guy makes a far superior torch holder for the plasmacam. This thing has saved me so much headache it is unreal! It is around sixty to seventy buck range and very well made and will never wear out. It is cnc machined out of aluminum. Changing it over from the original one takes mere minutes. The thing makes changing the tips so much easier it is hard to imagine that Plasmacam does not make something similar themselves. Anyway I ordered mine from him and it was here very quick. Check eBay if you want to use paypal or contact him directly. I may post a pic of the part but last time I checked it was on eBay.

This is the part here. This is the only part you should or will need to to buy for your Plasmacam. I have had mine for almost three years and have never had to fix a thing!

Level Zero Motorsports

www.levelzeromotorsports.com

Anyway I will be adding a few more pics here in the next while so stay tuned. If you have any questions etc feel free to email me at roycmackey@telus.net

Cheers!!!

If You get on my contact list you can get updates every so often on new work and shows etc that I have coming up. These are titled LIVE ART NEWS IN AMERICA and go out every month or so. Keep up to date on new work, latest books and other funny stuff. Just to note I never sell or give out emails to anyone for any reason.

ph. 604-269-3500